Regulations in pharmaceuticals, life sciences, and biotech demand unwavering compliance and a focus on continuous quality improvement. One of the most persistent challenges faced by Quality Assurance and Regulatory Affairs professionals is implementing a truly effective CAPA (Corrective and Preventive Action) program.

While the concept of a CAPA program is widely recognized as essential for regulatory compliance and operational excellence, its execution is rarely straightforward. Without clear strategies and reliable insights, even well-intentioned CAPA efforts can fall short, leading to repeated issues and increased regulatory risk.

To overcome these challenges, organizations need to design and implement CAPA programs that are not only compliant but also strategically aligned with quality and risk management goals. This means using actionable data, applying best practices, and creating a culture of continuous improvement across all levels of the organization.

TL;DR

- A CAPA program systematically corrects and prevents quality and compliance issues.

- You’ll learn how to structure, implement, and assess a CAPA process

- Discover how CAPA strengthens audit readiness and minimizes regulatory risk.

- Explore tools and strategies to streamline CAPA workflows and drive continuous improvement.

What is a CAPA Program?

It involves investigating the root cause of non-conformances, deviations, or adverse events and implementing corrective actions to fix the issue and preventive actions to ensure it doesn’t happen again.

As a result, a CAPA system is a vital component of any modern quality management framework, helping ensure the consistency, reliability, and integrity of the products and services a company delivers.

According to the U.S. Food and Drug Administration (FDA), the purpose of the CAPA program is to gather and analyze data, identify and investigate product or quality issues, and implement effective actions to correct the problem and prevent it from happening again.

What is the Purpose of the CAPA Program?

The primary goals of a CAPA program are:

- Corrective Action: Fixing existing problems quickly and thoroughly.

- Preventive Action: Identifying and mitigating potential future risks before they escalate.

- Continuous Improvement: Improving processes to ensure long-term compliance and quality.

An effective CAPA program goes beyond simply addressing issues. It helps build a culture of quality, transparency, and accountability throughout the organization.

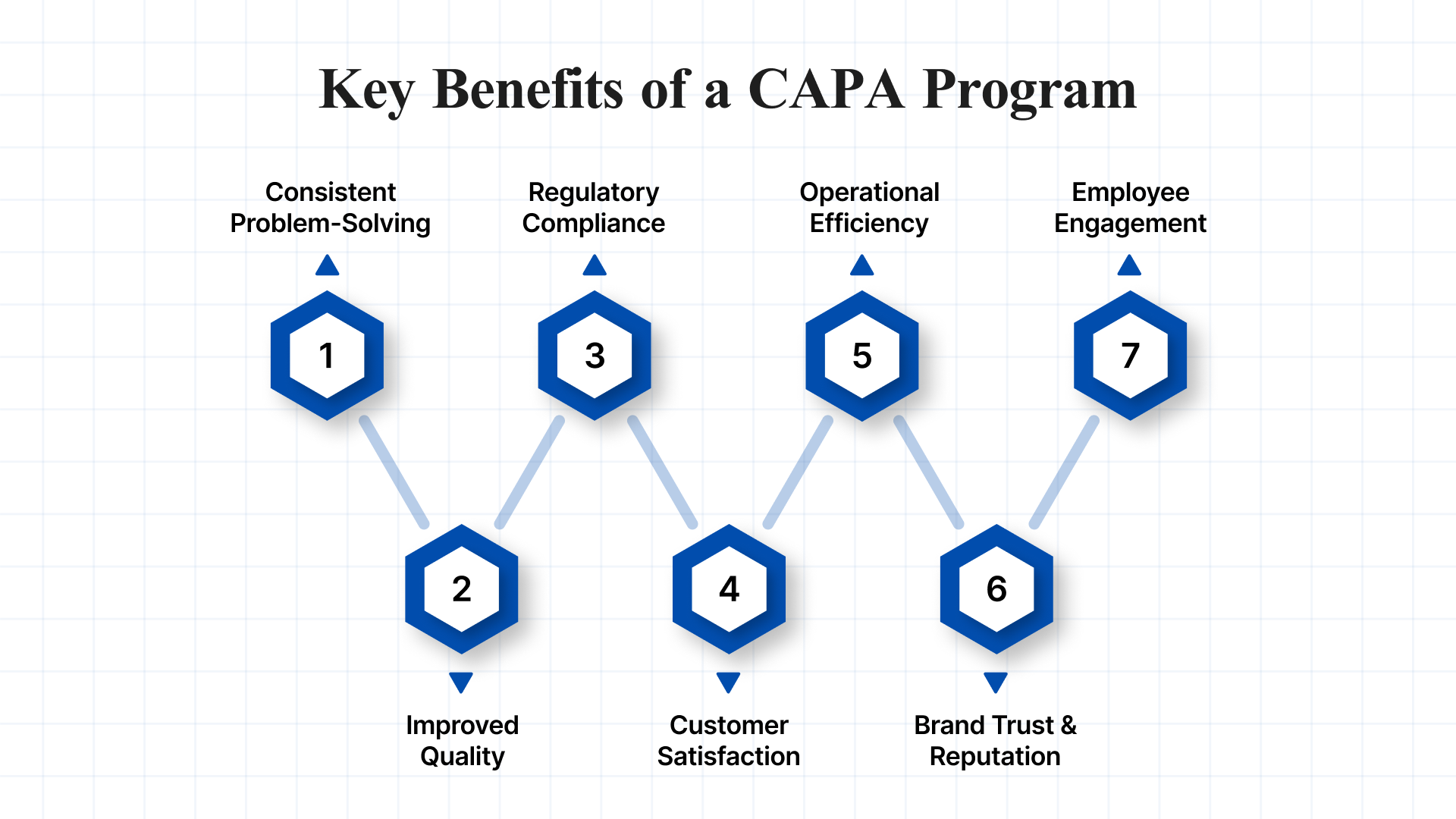

Key Benefits of a CAPA Program

Identifying a problem is only the first step. Solving it and preventing it from happening again requires a structured approach and strong team collaboration. This is where a well-defined CAPA process becomes a vital part of your business strategy. Here’s why it matters.

1. Creates a Consistent Problem-Solving Approach

One of the key benefits of a CAPA system is that it provides a standardized method for identifying, analyzing, and resolving issues. Without a clear process, teams may miss important steps or struggle to manage problems effectively.

2. Maintains Product Quality and Reduces Defects

The primary benefit of CAPA is improving the quality of products or services. By identifying and addressing issues before they escalate, CAPA ensures that customers receive products that meet high standards. This also helps reduce defects, rework, and waste, ultimately improving the overall quality.

3. Supports Regulatory Compliance

For many industries, particularly healthcare, pharmaceuticals, and food manufacturing, compliance with regulatory standards is not optional. CAPA processes are often required by regulatory bodies like the FDA, ISO, and GMP. By implementing CAPA, companies ensure they remain compliant and avoid costly fines, recalls, and reputational damage.

4. Improves Customer Satisfaction

An effective CAPA process allows you to respond to customer complaints in a timely and structured manner. It also provides a way to gather feedback and make meaningful improvements. When customers feel heard and see positive changes, they are more likely to trust your brand and remain loyal over time.

5. Boosts Operational Efficiency

By resolving recurring issues, CAPA minimizes waste, lowers costs, and improves resource use. The result is streamlined operations and a more sustainable, productive business model.

6. Builds Trust and Brand Reputation

A visible commitment to quality and improvement improves your reputation. Customers are more likely to trust and stay loyal to brands that consistently deliver safe, reliable products and services.

7. Increases Employee Involvement

Involving staff in the CAPA process builds a culture of accountability and safety. Employees feel valued and are more likely to contribute ideas, leading to a more engaged and innovative workforce.

Also read: Effective FDA Form 483 Response Strategies

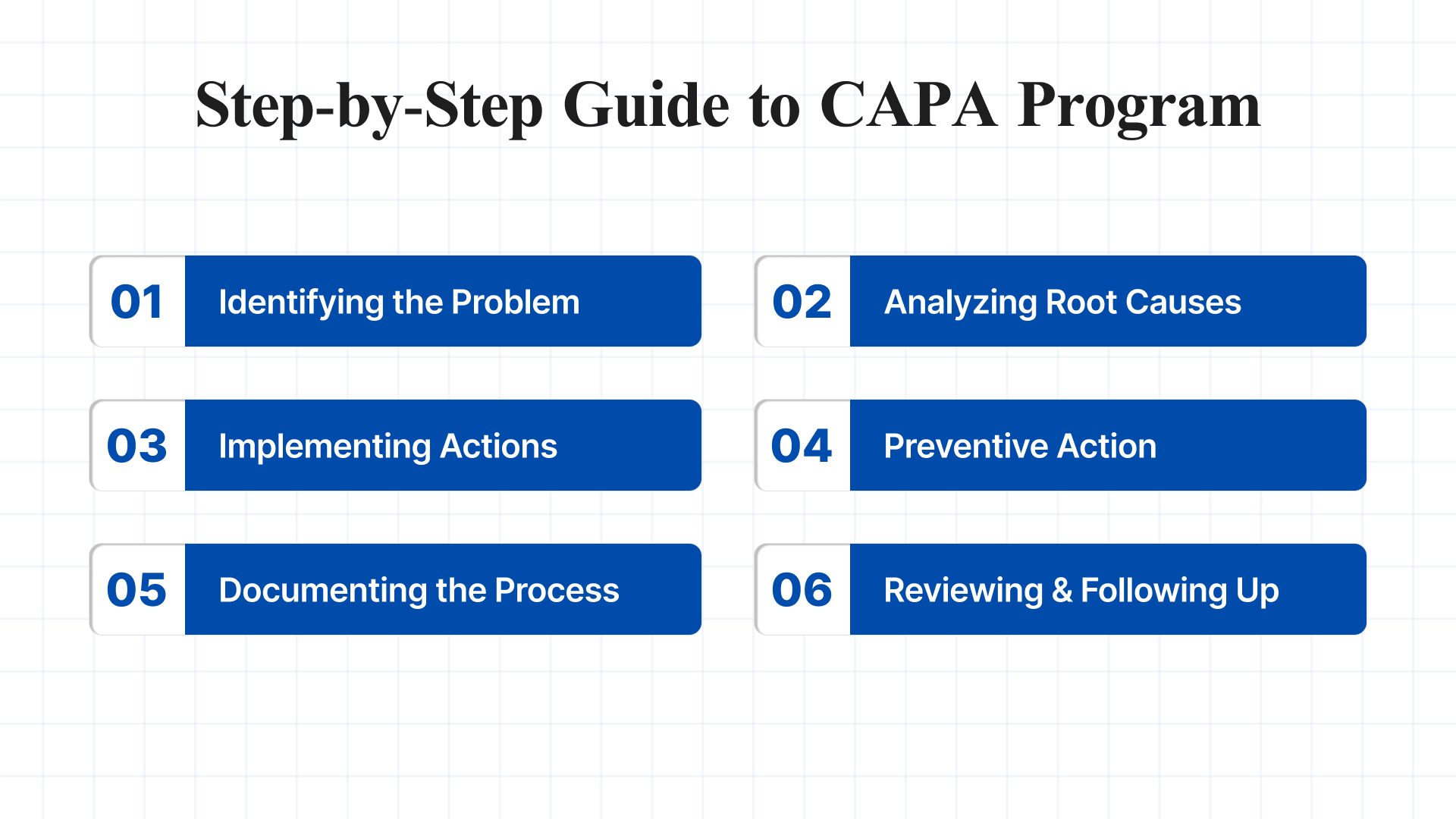

Step-by-Step Guide to a Successful CAPA Program

Here’s how to implement a CAPA program that goes beyond compliance and delivers better results.

1. Identifying the Problem

This initial step involves recognizing and clearly documenting any quality issues, deviations, or nonconformities from established standards. It lays the groundwork for the entire CAPA process. Problems may be identified through various channels, such as customer complaints, internal audits, quality checks, or regulatory inspections.

2. Analyzing Root Causes

Once an issue is identified, a thorough investigation is needed to determine not just the immediate cause but also any underlying systemic or procedural flaws. It involves collecting data, reviewing related processes and procedures, and using root cause analysis techniques to uncover the core contributors to the problem. This is typically done using methods like the 5 Whys, Fishbone Diagram, or Failure Mode and Effect Analysis (FMEA).

3. Implementing Corrective Actions

Corrective actions are designed to resolve the issue and eliminate its root cause. This phase should be carefully planned, documented, and executed in alignment with your organization’s quality goals and regulatory standards. Examples include updating procedures, retraining staff, modifying systems, or repairing defective products to address and contain the issue effectively.

4. Preventive Action

Based on the findings, preventive actions are then designed to ensure that similar problems do not occur in the future. These actions might involve improving processes, implementing new controls, or training staff on new protocols.

5. Documenting and Verifying the Process

Thorough documentation ensures traceability and regulatory compliance. It provides a detailed record of the entire CAPA process, which can be used during audits or reviews.

Verification involves evaluating whether the corrective actions taken have successfully resolved the issue and prevented recurrence, often through follow-up testing or performance analysis.

6. Reviewing and Following Up

In the final step, organizations assess the long-term success of the CAPA process. This includes monitoring outcomes and confirming that improvements are sustained over time. Follow-up activities might involve periodic audits, ongoing performance tracking, and regular reviews to support continuous improvement and maintain compliance.

With Atlas Compliance’s AI-powered document search, you can accelerate root cause analysis and CAPA planning by quickly surfacing relevant regulatory precedents and internal data.

How Does CAPA Connect to FDA Inspections?

The U.S. Food and Drug Administration (FDA) plays a critical role in enforcing regulatory compliance. When the FDA conducts inspections, the presence (or absence) of an effective CAPA system is often a key focus. FDA inspection reports, such asForm 483s, warning letters, and CFR citations, highlight where a company’s quality management system may be lacking, particularly in areas like CAPA.

Corrective and Preventive Action (CAPA) plays a central role in FDA inspections, particularly for companies regulated under21 CFR Part 820 (Quality System Regulation for medical devices) and 21 CFR Part 211 (for pharmaceuticals). A strong CAPA process is not just a regulatory requirement. It is also a major focus during FDA audits and inspections, often determining whether a company passes or faces enforcement action.

Why is CAPA a Focus Area for the FDA?

1. Regulatory Requirement: Under 21 CFR 820.100, medical device manufacturers are required to establish and maintain procedures for implementing corrective and preventive actions. The FDA expects companies to identify root causes of nonconformities, correct them, and implement preventive measures to avoid recurrence.

2. Quality System Indicator: CAPA is often considered a “window” into a company’s entire quality system. If CAPA is weak, it usually signals broader systemic issues. FDA inspectors typically examine the CAPA system early during audits to assess how well a company identifies, documents, investigates, and resolves quality problems.

3. Common Source of 483s and Warning Letters: CAPA-related violations are among the most frequently cited in FDA Form 483 observations and Warning Letters. Common issues include:

- Inadequate root cause analysis

- Poor documentation

- Failure to verify or validate corrective actions

- Lack of effectiveness checks

- Delays in addressing nonconformances

What Inspectors Look For in CAPA Systems?

During inspections, FDA investigators typically examine:

- Whether nonconformances are appropriately identified and documented

- The thoroughness of root cause analysis

- If corrective actions are implemented effectively and promptly

- How well effectiveness checks are conducted and documented

- Integration of CAPA with complaints, audits, and risk management

- Whether management reviews CAPA trends for continuous improvement

They may request to see:

- CAPA procedures (SOPs)

- Records of CAPA investigations

- Training records tied to CAPA changes

Data trends or metrics tracking CAPA performance.

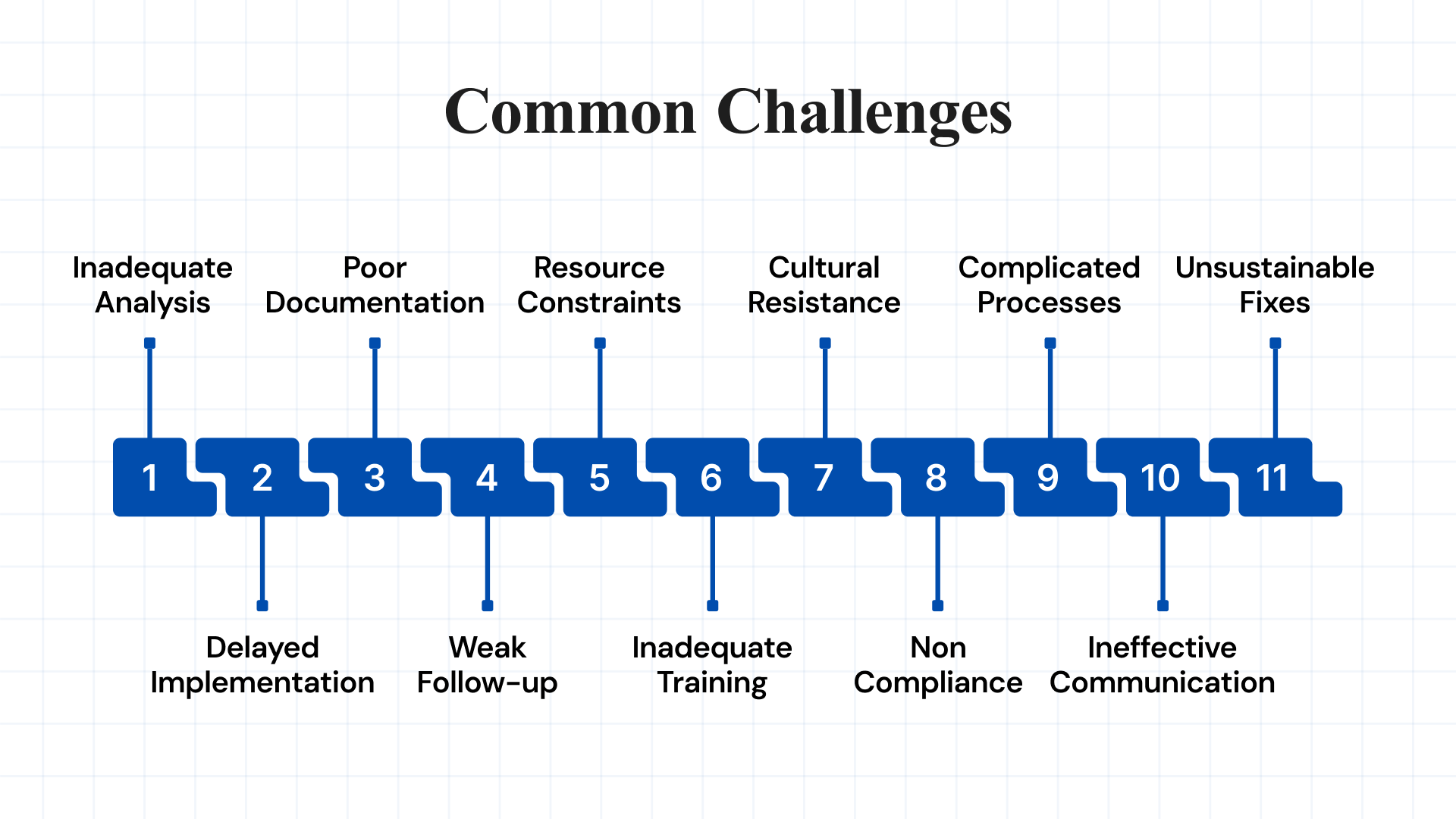

Common Challenges and How to Overcome

The Corrective and Preventive Action (CAPA) process is essential for identifying, investigating, and resolving issues related to quality management, especially in industries like manufacturing, pharmaceuticals, and healthcare. However, it comes with its own set of challenges. Below are some common challenges faced in the CAPA process:

1. Inadequate Root Cause Analysis

- Challenge: Teams often jump to conclusions or rely on assumptions, leading to incomplete or inaccurate analysis.

- Solution: Use structured tools like the FMEA to ensure comprehensive and objective root cause identification.

2. Delayed Implementation of Actions

- Challenge: Resource limitations or lack of urgency can cause delays in executing corrective or preventive actions.

- Solution: Set clear timelines, assign responsibility, and integrate CAPA actions into project management systems to maintain momentum.

3. Poor Documentation

- Challenge: Inconsistent or incomplete CAPA records can cause confusion and make audits difficult.

- Solution: Standardize documentation practices using digital CAPA systems to improve traceability and compliance.

4. Weak Follow-up and Effectiveness Checks

- Challenge: Actions are implemented but not evaluated for actual impact, allowing issues to recur.

- Solution: Define clear metrics and conduct post-implementation reviews to confirm actions have resolved the root cause.

5. Resource Constraints

- Challenge: Limited time, staff, or budget can prevent thorough CAPA execution.

- Solution: Prioritize high-risk issues, allocate necessary resources, and consider dedicated CAPA teams or support tools.

6. Inadequate Training

- Challenge: Employees may not fully understand CAPA processes, leading to inconsistent execution.

- Solution: Provide targeted CAPA training and refreshers, along with resources for cross-functional communication.

7. Cultural Resistance to Change

- Challenge: Fear of blame or lack of openness can suppress reporting and engagement in CAPA.

- Solution: Promote a non-punitive, improvement-focused culture where issues are openly discussed and addressed constructively.

8. Non-Compliance with Regulations

- Challenge: Failure to follow industry standards and regulatory expectations can result in penalties or legal issues.

- Solution: Ensure CAPA processes align with regulations like ISO 13485, FDA 21 CFR 820, and ICH Q10, and update them regularly.

9. Overcomplicated Processes

- Challenge: Excessive bureaucracy or overly complex workflows can stall progress.

- Solution: Simplify CAPA procedures and focus on practical, easily executable actions that can be tracked and measured.

10. Ineffective Communication

- Challenge: Poor coordination among departments or teams can create confusion and delays.

- Solution: Establish clear communication channels, regular status updates, and shared access to CAPA progress information.

11. Unsustainable Fixes

- Challenge: Short-term patches may address symptoms but not the underlying issue, risking recurrence.

- Solution: Embed CAPA within a continuous improvement framework to drive long-term change and prevent future problems.

How Does Atlas Compliance Support CAPA Programs?

While building a CAPA program is essential, managing it efficiently across multiple data points, stakeholders, and regulatory sources can be a complex task. Here’s how Atlas Compliance simplifies the process.

- FDA Inspection Intelligence: Weekly-updated reports, warning letters, and inspection data from 2004 onward.

- AI-Powered Search: Utilizes natural language processing to quickly identify relevant regulatory precedents and internal data, enabling faster and more accurate root cause analysis and CAPA planning

- Predictive Analytics: It uses historical inspection data and machine learning to forecast likely future regulatory focus areas, allowing you to proactively adjust your CAPA strategies.

- Regulatory Surveillance: Get notified of regulatory changes that might impact your CAPA strategies.

- Unified Platform: Align quality, regulatory, and compliance teams on one intelligent platform.

With Atlas Compliance, companies can track inspections, update regulatory changes, and prepare for audits, all from a single, integrated solution. This leads to greater predictability, improved decision-making, and more impactful outcomes from your CAPA program.

Conclusion

Incorporating a CAPA program into your quality processes is essential for ensuring product quality, regulatory compliance, and continuous improvement. However, managing CAPA effectively in highly regulated industries can be complex and time-consuming. From meeting changing compliance standards to handling large volumes of data, the challenges are significant.

That’s where technology makes a difference. Platforms like Atlas Compliance offer a smarter way to manage your CAPA program. With AI-powered insights, predictive analytics, and access to FDA inspection intelligence, your team can make informed decisions, reduce risk, and stay audit-ready. By integrating advanced tools into your CAPA process, you not only streamline operations but also strengthen compliance and build a foundation for long-term success.

[Get a personalized demo] and see how Atlas Compliance can strengthen your compliance strategy.

FAQs

Q1. What are CAPA requirements?

FDA regulations require CAPA systems to operate as a closed-loop process that can document, review, approve, and manage all CAPA activities and outcomes. Each action taken must be verified and validated to ensure effectiveness. Comprehensive documentation is essential to demonstrate compliance and traceability during audits or inspections.

Q2. What is a CAPA management system?

A CAPA management system refers to the structured process within a quality management framework that addresses quality-related problems. It identifies existing issues, develops action plans to correct them, and introduces measures to prevent them from happening again. These systems help enhance product quality, ensure safety, boost customer satisfaction, and maintain compliance with FDA regulations.

Q3. What is the purpose of a CAPA system?

A CAPA system is a component of a quality management system that focuses on identifying, analyzing, and resolving quality issues. Its purpose is to investigate the root causes of problems and implement corrective and preventive actions to eliminate current issues and prevent them from recurring.

Q4. How is a CAPA system implemented?

Implementing a CAPA system typically follows the PDCA (Plan, Do, Check, Act) methodology:

- Plan: Define requirements, identify necessary resources, acquire tools such as CAPA software, and assign responsibilities.

- Do: Develop procedures, train staff, and establish clear SOPs outlining how the CAPA process will operate.

- Check: Evaluate the effectiveness of your CAPA system through internal audits or performance reviews.

- Act: Deploy the CAPA process, monitor its performance continuously, and make improvements based on results.