Pre-Approval Inspections (PAIs) are high-stakes checkpoints in FDA-regulated industries that can significantly impact product approval and market entry. Many companies, regardless of size or past experience, often find themselves unprepared for the depth and rigor of a PAI.

We understand that facing a pre-approval inspection FDA can feel daunting and stressful, especially given the complexity and critical importance of these evaluations for your product’s success.

Even experienced organizations must invest time and resources to ensure PAI readiness. Internal teams may be stretched thin, prompting the need for external auditors to conduct mock inspections and support remediation efforts. Still, mock audits alone aren’t enough; adequate preparation must cover staff training, compliance alignment, documentation, and process validation across functions.

This guide provides a focused overview of what PAIs entail, what companies can expect during the process, and how to develop a structured, cross-functional approach to preparation, drawing on practical insights from seasoned FDA professionals.

TL;DR

- Understand the PAI’s Purpose: The FDA conducts PAIs to verify facility readiness, data integrity, and alignment with application details before approving new drugs or major changes to existing licenses.

- Know When PAIs Are Triggered: Risk factors like new products, past compliance issues, or complex processes can prompt a PAI. Facilities listed in NDAs, ANDAs, BLAs, and PMAs are common targets.

- Build Cross-Functional Readiness: Assemble an inspection team, train staff, validate processes, and conduct gap analyzes or mock inspections, preferably with external experts.

- Ensure Documentation & Systems Are strong: Validate CMC sections, batch records, SOPs, and quality systems. Data integrity, traceability, and CGMP compliance are non-negotiable.

What is an FDA Pre-Approval Inspection?

A Pre-Approval Inspection (PAI) is conducted by the Food and Drug Administration (FDA) to confirm that a manufacturing facility named in a drug application can consistently produce a safe, effective product and that the data submitted in the application is accurate and complete.

The primary purpose of a PAI is to evaluate the facility’s ability to manufacture the proposed product at commercial scale and in compliance with regulatory standards. This includes verifying that the site operations align with the details in the application and that robust systems are in place to ensure ongoing product quality.

PAIs are typically required for manufacturing facilities listed for the first time in applications such as:

- New Drug Applications (NDAs) and Abbreviated New Drug Applications (ANDAs), for both human and veterinary drugs

- Biologics License Applications (BLAs)

- Premarket Approval (PMA) submissions for medical devices

During the inspection, FDA investigators assess whether:

- The facility aligns with what was described in the application

- Manufacturing processes are reliable and scalable

- Analytical methods are appropriate and validated

- All data provided is authentic and accurately reflects operations

- The site is in full compliance with Current Good Manufacturing Practices (CGMP)

The FDA has wide discretion regarding the timing and scope of PAIs. The agency’s Compliance Program Guidance Manual (CPGM) 7346.832outlines the criteria for prioritizing these inspections.

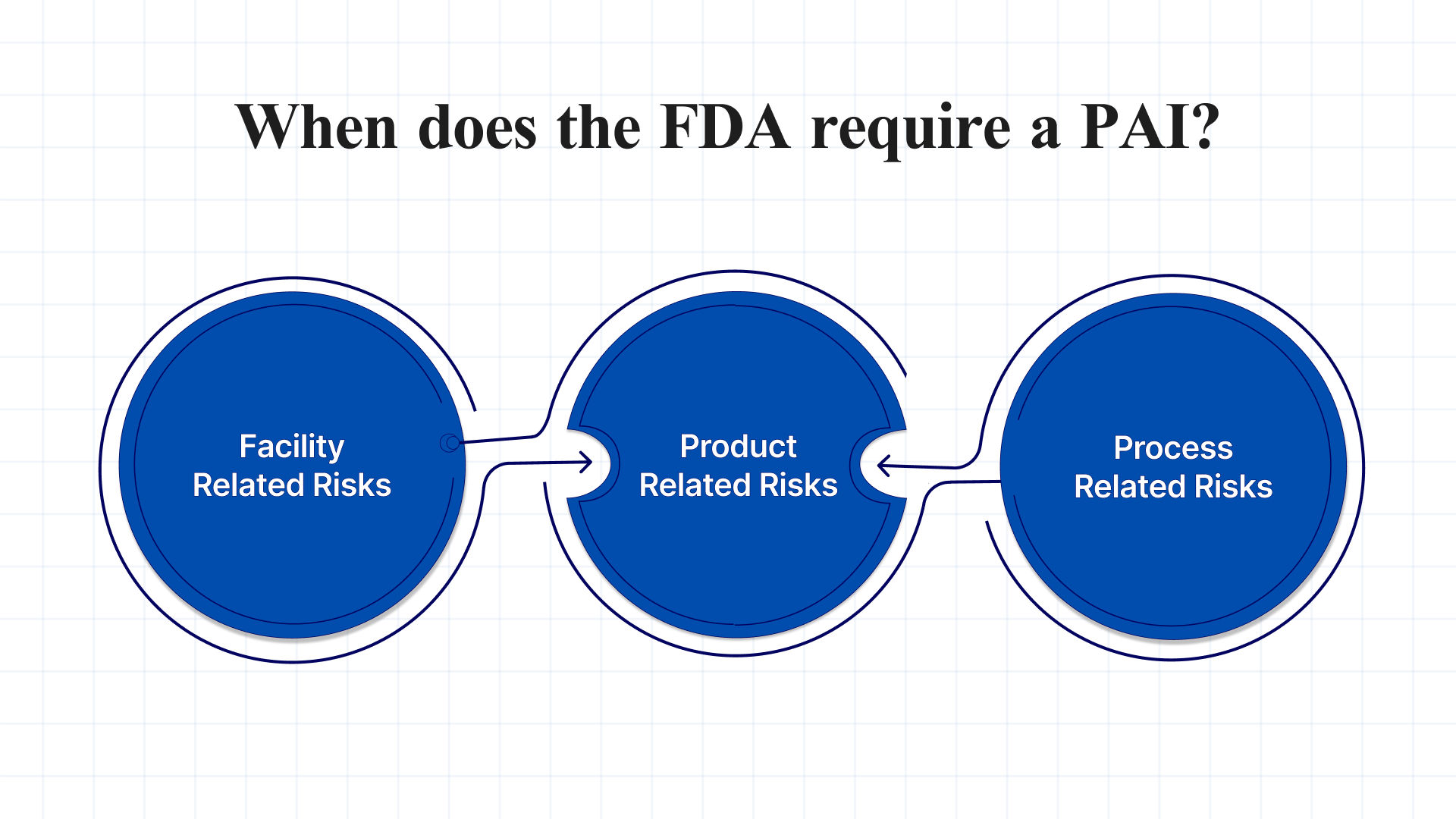

When does the FDA require a Pre-Approval Inspection (PAI)?

The FDA performs Pre-Approval Inspections based on a risk-based assessment of the facility, product, and manufacturing process. Inspections are more likely when certain risk factors are present, including:

1. Facility-Related Risks:

- History of CGMP compliance issues

- Prior Field Alert Reports (FARs) tied to the product

- Recent product recalls

- Multiple applications submitted simultaneously

2. Product-Related Risks:

- New molecular entities

- First-time application by the sponsor

- First ANDA submitted for a reference drug

- Known adverse events, stability concerns, or complaints

- Intended for high-risk patient populations or serious conditions

- Designated as a breakthrough therapy or addressing a drug shortage

3. Process-Related Risks:

- Narrow therapeutic index (e.g., 95–105% potency range)

- High-risk active pharmaceutical ingredient (e.g., animal-derived)

- Use of advanced technologies (e.g., PAT, NIR, QbD)

- Incomplete development data or vague batch records

- Complex or significantly different manufacturing processes compared to previous filings

The FDA uses these criteria to determine the necessity and scope of a PAI, prioritizing inspections where the potential risk to product quality or patient safety is highest.

Key Objectives of a Pre-Approval Inspection (PAI)

A Pre-Approval Inspection (PAI) is conducted to evaluate the readiness and reliability of a manufacturing site before FDA product approval. The inspection focuses on three core objectives:

1. Readiness for Commercial Manufacturing: Assess whether the facility has a robust quality system in place to ensure adequate control over commercial manufacturing operations and the overall facility.

2. Conformance to Application: Confirm that the manufacturing processes, formulations, and analytical methods match those described in the Chemistry, Manufacturing, and Controls (CMC) section of the application, covering biobatch, pivotal clinical batches (if applicable), commercial-scale batches, and active pharmaceutical ingredients (APIs).

3. Data Integrity Audit: Examine raw data (both hardcopy and electronic) to verify the authenticity and accuracy of the information submitted in the CMC section. This ensures that product reviewers can rely on the submitted data as complete, accurate, and representative of actual conditions.

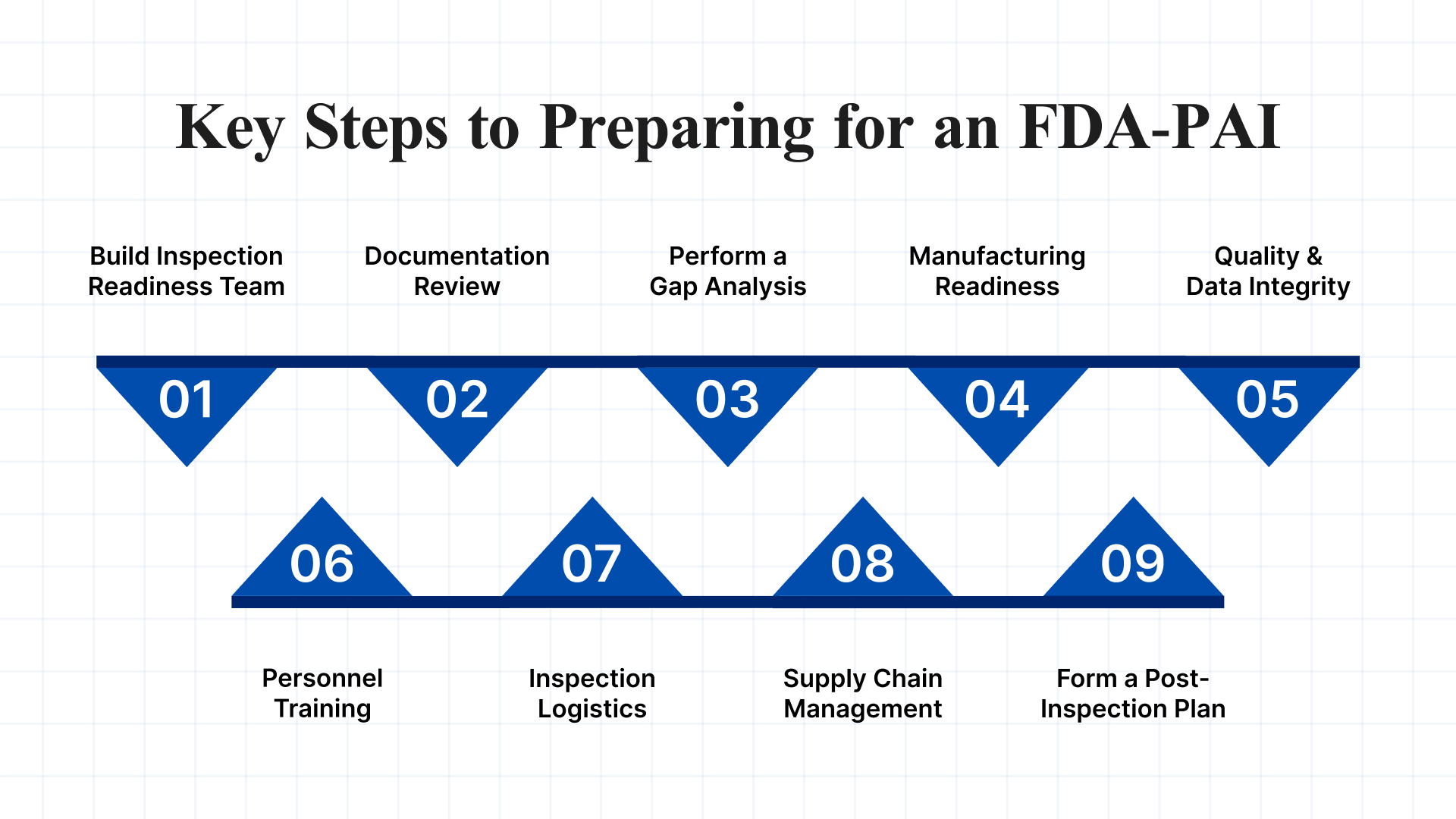

Key Steps to Preparing for an FDA Pre-Approval Inspection

Preparing for a Pre-Approval Inspection (PAI) is not a last-minute task; it’s a sustained, strategic process. The goal is to demonstrate consistent control, compliance, and readiness from the moment an FDA investigator arrives.

Below are the essential steps to build a strong foundation for a successful inspection.

1. Build a Cross-Functional Inspection Readiness Team

- Assemble a team representing quality, operations, regulatory, and technical services.

- Appoint a dedicated Project Manager with experience in quality systems.

- Identify SMEs (Subject Matter Experts) for each functional area.

- Establish backups for all critical roles.

- Define clear communication and escalation protocols.

- Create a rapid response plan for unannounced inspections.

2. Conduct a Comprehensive Documentation Review

Ensure all required documents are complete, accurate, and readily accessible:

- Chemistry, Manufacturing, and Controls (CMC) section

- Master Production Batch Records

- Development and validation reports

- Quality control (QC) and analytical methods

- Process validation and technology transfer records

- Stability studies and specifications.

- Organize documents in both electronic and hard copy formats for quick retrieval during the inspection.

3. Perform a Gap Analysis and Mock Inspection

- Compare current documentation and practices against FDA requirements and guidance (e.g., Compliance Program Guidance Manual 7346.832).

- Identify and address any gaps or deficiencies.

- Conduct at least one mock inspection, ideally with an independent third party, to simulate the FDA process and identify areas for improvement.

4. Ensure Manufacturing and Facility Readiness

- Verify that manufacturing processes, equipment, and facilities are fully qualified and validated.

- Confirm that all equipment calibration, maintenance records, and environmental monitoring data are up to date.

- Ensure facility layout, utilities, and environmental controls meet regulatory expectations.

5. Strengthen Quality Systems and Data Integrity

- Review and update Standard Operating Procedures (SOPs) for all critical processes.

- Ensure robust quality assurance (QA) and quality control (QC) systems are in place.

- Audit data integrity practices, including manual and electronic records, to ensure traceability and reliability.

6. Train and Prepare Personnel

- Provide inspection readiness training for all subject matter experts (SMEs) and staff who may interact with FDA inspectors.

- Conduct role-playing or mock interviews to prepare key personnel for questions and document requests.

7. Prepare for Inspection Logistics

- Designate an inspection room and ensure all necessary resources (documents, equipment, internet access) are available.

- Assign an escort team to accompany inspectors and manage document flow.

- Develop a clear communication plan for responding to inspector requests and questions.

8. Review and Test Supply Chain and Vendor Management

- Ensure all vendors and suppliers are qualified, and that documentation is available.

- Confirm that material traceability, shipping, and storage records are complete.

9. Establish a Post-Inspection Response Plan

- Prepare to address any FDA Form 483 observations promptly and thoroughly.

- Develop a corrective and preventive action (CAPA) process for any issues identified during the inspection.

Outcomes of the Pre-Approval Inspection (PAI)

Following the conclusion of a Pre-Approval Inspection (PAI), the FDA’s lead investigator will issue a recommendation that significantly impacts the trajectory of the application. There are generally two possible outcomes: recommendation for approval or recommendation to withhold approval.

Recommendation for Approval

A recommendation for approval suggests that the inspection did not uncover any major deficiencies in the facility’s operations or compliance systems. This outcome indicates that:

- The facility is in a state of control and compliant with Current Good Manufacturing Practices (CGMP).

- The data submitted in the Chemistry, Manufacturing, and Controls (CMC) section of the application is consistent with what is observed and verified on-site.

- The manufacturing processes, analytical methods, and documentation practices meet regulatory expectations.

Once FDA approval is granted, your facility becomes subject to routine CGMP inspections. The frequency of these inspections is determined through a risk-based approach, taking into account factors like product type, compliance history, and public health risk.

- Domestic facilities can generally expect inspections approximately every two years.

- International sites are typically given notice before the FDA conducts an inspection, but they are held to the same standards as U.S.-based firms.

Important note: Even when approval is recommended, FDA investigators may still issue observations in the form of a Form 483. These observations must be addressed through a formal written response that demonstrates your corrective actions and commitment to continuous improvement. Failing to address or respond inadequately to these observations can impact future inspections.

Case Study: Nonconformance to Application

Even well-resourced organizations can run into issues during a pre-approval inspection with the FDA due to misalignment between application details and actual site practices. One common pitfall is failing to meet commitments made in the Chemistry, Manufacturing, and Controls (CMC) section of the submission.

Case Example: Inadequate Container Closure Qualification

During a recent inspection, a firm received a recommendation to withhold approval due to a significant inconsistency in their application:

- The drug substance was intended to be packaged in LDPE (Low-Density Polyethylene) bags, as specified in the application.

- However, stability studies submitted in support of the application were conducted using amber glass bottles, a different container-closure system entirely.

- At the time of inspection, the firm lacked any data to support the suitability or stability of the API when stored in LDPE bags.

- In response, the firm stated it would temporarily revert to using amber glass bottles until adequate stability data for LDPE packaging could be generated.

Inspection Outcome: Because the actual packaging system used in the application had not been properly qualified or supported by stability data, the FDA recommended withholding approval. This outcome highlighted a critical disconnect between the firm’s application commitments and their execution on-site.

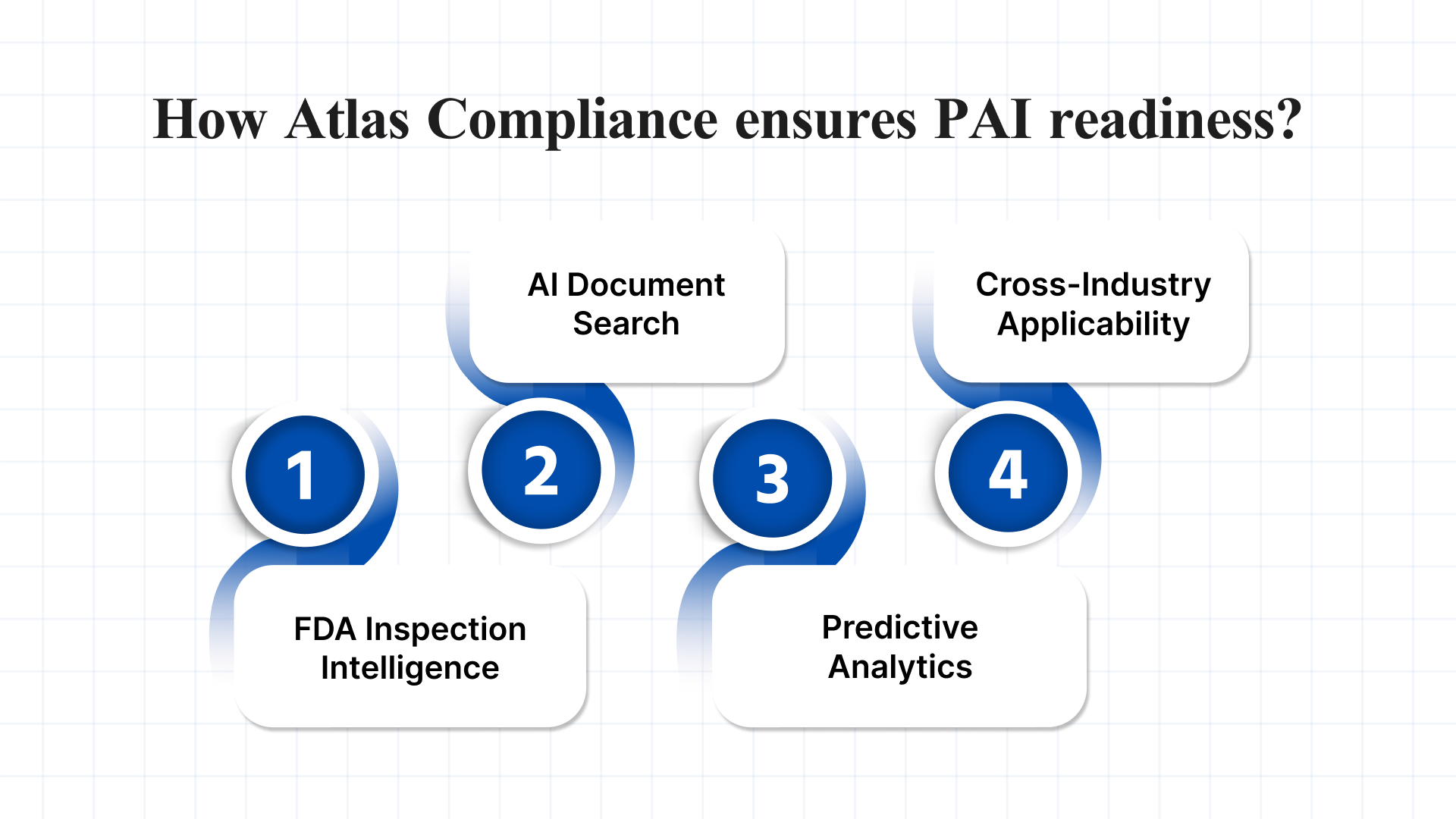

How Atlas Compliance Supports Pre-Approval Inspection (PAI) Readiness

Preparing for a Pre-Approval Inspection (PAI) requires more than just documentation—it demands continuous insight, rapid access to regulatory intelligence, and proactive risk management. Atlas Compliance helps companies meet these demands through a centralized, AI-powered platform built specifically for FDA-regulated industries.

Here’s how we strengthen your PAI readiness:

Comprehensive FDA Inspection Intelligence

- Access a vast repository of FDA inspector reports dating back to 2004, updated weekly.

- Analyze Form 483 observations, warning letters, and CFR citations across therapeutic areas and manufacturing types.

AI-Powered Document Search

- Use natural language processing (NLP) to quickly locate relevant regulatory data, SOPs, and compliance records.

- Streamline preparation by extracting insights from past inspection documents and aligning internal documentation accordingly.

Predictive Compliance Analytics

- Turn fragmented regulatory data into predictive insights with machine learning models.

- Anticipate inspection focus areas, uncover risk patterns, and proactively mitigate potential compliance gaps.

Cross-Industry Applicability

- Gain actionable intelligence not just for human drugs but also for biologics, medical devices, cosmetics, and food manufacturing.

- Manage supplier risk and prepare comprehensively, regardless of your product portfolio.

With Atlas Compliance, pharmaceutical and life sciences companies can transform inspection readiness from a reactive process into a strategic, data-driven discipline. Whether you’re weeks away from a PAI or building long-term inspection resilience, we help you stay one step ahead.

Conclusion

FDA pre-approval inspections are a vital part of the drug approval process, and preparation is key to ensuring a smooth and successful outcome. By understanding FDA requirements, reviewing previous inspection reports, ensuring proper documentation, performing internal audits, and utilizing advanced compliance tools, you can improve your chances of passing the inspection with ease.

Atlas Complianceimproves this process by turning complex regulatory data into actionable intelligence. With AI-powered tools for document search, inspection analytics, and risk prediction, we help you stay inspection-ready and ahead of compliance challenges, before the FDA even knocks.

Ready to simplify your FDA inspection process and future-proof your compliance strategy?

Book a free demo with us today!

FAQs

Q1. What is the difference between a Pre-License Inspection (PLI) and a Pre-Approval Inspection (PAI)?

A1. A Pre-License Inspection (PLI) is conducted by the FDA for new biological products to ensure that the manufacturing facility complies with regulatory requirements before a new biologics license is granted.

In contrast, a Pre-Approval Inspection (PAI) is conducted when there are significant changes to an already approved Biologics License Application (BLA), such as modifications to manufacturing processes, facilities, or equipment. Both inspections aim to verify regulatory compliance before approving either a new license or a major change to an existing one.

Q2. What is the purpose of an FDA Pre-Approval Inspection?

A2. An FDA Pre-Approval Inspection (PAI) is conducted to assess a pharmaceutical manufacturer’s compliance with the FDA’s regulations before a new drug or biologic is approved for market. The primary goal is to verify that the company’s facilities, processes, and documentation adhere to the FDA’s Current Good Manufacturing Practices (CGMP). Successful completion of the PAI is essential for the product’s approval.

Q3. How long does a pre-approval inspection take?

A3. The length of a pre-approval inspection can vary depending on the complexity of the product and the manufacturer’s operations. Generally, a PAI lasts between 1 to 2 weeks, but it may be extended if significant issues are found or if the inspector requires more time to review documentation and facilities. Being well-prepared and having all relevant documents readily available can help speed up the process.

Q4. What is included in the FDA pre-approval inspection checklist?

A4. The FDA pre-approval inspection checklist typically includes evaluating the manufacturer’s adherence to CGMPs, reviewing production and quality control systems, inspecting facilities and equipment, and ensuring all documentation is complete and up-to-date. Inspectors will focus on areas such as manufacturing processes, batch records, lab testing, and packaging to ensure that everything complies with regulatory standards.