FDA QSIT inspection readiness is often a major source of stress for companies in regulated industries, largely due to the high stakes and complex requirements involved. Many businesses are caught off guard not by what’s inspected but by how quickly the process begins the moment an FDA inspector walks through the door. From presenting credentials and issuing Form FDA 482 (Notice of Inspection) to initiating an opening meeting and setting up a base of operations within your facility, every step requires clarity, coordination, and compliance.

So, the real issue many companies face isn’t a lack of quality but a lack of preparation in how that quality is demonstrated. A clear, practiced approach is essential to ensure your team is confident, your systems are transparent, and your facility is inspection-ready at any time.

TL;DR

- FDA QSIT inspections follow a top-down, subsystem-focused approach, starting with management controls and drilling down into implementation, documentation, and outcomes.

- Be prepared to demonstrate compliance across Management Controls, CAPA, Design Controls (if applicable), and production and process controls.

- Inspectors will evaluate both your written procedures and how well they are implemented on the ground, including sampling records and interviewing personnel.

- FDA aims to identify gaps in your overall quality system, not just isolated errors, making consistency across all levels of your organization essential.

What Is an FDA QSIT Inspection?

Since January 1, 2000, QSIT has served as the primary inspection framework used by FDA investigators to evaluate medical device manufacturers globally. An FDA QSIT (Quality System Inspection Technique) inspection is a standardized approach the U.S. Food and Drug Administration uses to evaluate the quality systems of regulated manufacturers.

This includes companies involved in pharmaceuticals, medical devices, biologics, food, and cosmetics. The QSIT methodology focuses on assessing whether a company’s quality system is established correctly, maintained effectively, and meets regulatory standards.

The QSIT framework is outlined in Compliance Program (CP) 7382.845, Inspection of Medical Device Manufacturers, which provides guidance to FDA field and center staff for conducting inspections and enforcing key regulatory requirements. These include:

- The Quality System Regulation (21 CFR Part 820)

- Medical Device Reporting (21 CFR Part 803)

- Medical Device Tracking (21 CFR Part 821)

- Corrections and Removals (21 CFR Part 806)

- Registration and Listing (21 CFR Part 807)

Key Characteristics of the QSIT Method

- Subsystem-Oriented: Inspections focus on four major quality system subsystems as Management Controls, CAPA, Design Controls, and Production & Process Controls.

- Top-Down Logic: Inspectors start by reviewing management-level systems and then drill down into procedures, records, and implementation.

- Sampling-Based: The FDA uses data sampling to evaluate records and identify trends or compliance risks without inspecting every file.

- Flexible and Risk-Based: QSIT allows FDA to scale the depth of an inspection based on past compliance history and the potential impact on public health.

The QSIT method is not only used to detect noncompliance but also to evaluate whether a company’s quality system is strong, preventive, and aligned with regulatory expectations.

4 Major Subsystems of QSIT

Rather than performing a random or unfocused inspection, QSIT allows FDA investigators to concentrate on four critical subsystems:

- Management Controls: This subsystem evaluates how senior leadership ensures that the quality system is effectively established and maintained. It includes oversight of internal audits, management reviews, and the delegation of responsibility for compliance-related activities.

- Corrective and Preventive Actions (CAPA): CAPA focuses on how well a company identifies, investigates, and resolves quality issues to prevent recurrence. Inspectors will assess the effectiveness and documentation of your problem-solving processes and your ability to implement lasting fixes.

- Design Controls: For companies involved in product development, this subsystem reviews how design processes are planned, verified, validated, and documented. It ensures that products meet user needs, intended uses, and FDA safety and effectiveness standards.

- Production and Process Controls: This area examines how consistently and reliably your manufacturing processes produce quality products. It includes equipment calibration, environmental monitoring, in-process controls, and compliance with written procedures.

The QSIT inspection framework is designed to identify systemic issues that could compromise product quality or safety. Inspectors employ a top-down approach, beginning with management’s oversight of the quality system and progressing to documentation, implementation, and operational controls to assess a company’s adherence to compliance standards.

Top-Down Inspection Approach

The FDA’s QSIT inspection process follows a top-down methodology, which means inspectors begin by evaluating your company’s overarching systems and policies before examining specific documents and records. Here’s how this structured approach unfolds:

- Starts at the Management Level: Inspectors begin by assessing Management Controls, such as how your leadership ensures compliance with FDA regulations, allocates resources, and oversees quality-related decision-making.

- Focuses on System Effectiveness: The emphasis is not only on whether systems exist but also on how effectively they are implemented. Inspectors will want to see that your systems are working in practice, not just on paper.

- Reviews High-Level Quality Policies and Procedures: Policies such as your Quality Manual, SOPs (Standard Operating Procedures), and internal audit reports are reviewed to ensure they align with FDA expectations and reflect actual practices.

- Drills Down into Operational Records: Once high-level controls are reviewed, inspectors move deeper into the organization by examining supporting documentation, such as batch records, training logs, CAPA reports, and equipment maintenance logs.

- Follows the Flow of Decision-Making: Inspectors trace how decisions made by senior management influence day-to-day quality operations. This can involve reviewing how a risk identified during an internal audit led to a CAPA and how that CAPA was implemented on the production floor.

- Evaluate Compliance Consistency: The goal is to ensure that your entire quality system functions cohesively, from top-level strategy down to line-level execution.

- Identifies Systemic Weaknesses: By starting at the top, inspectors can more easily spot patterns, gaps, or inconsistencies that might indicate systemic noncompliance across multiple departments or processes.

- Enables Efficient Risk-Based Assessment: The top-down approach allows the FDA to focus its inspection resources on the areas of greatest potential risk, ensuring a more efficient and targeted evaluation.

This structured approach emphasizes control, visibility, and accountability at all levels of your quality system. Preparing your management team and ensuring alignment between policy and practice is essential for a successful QSIT inspection.

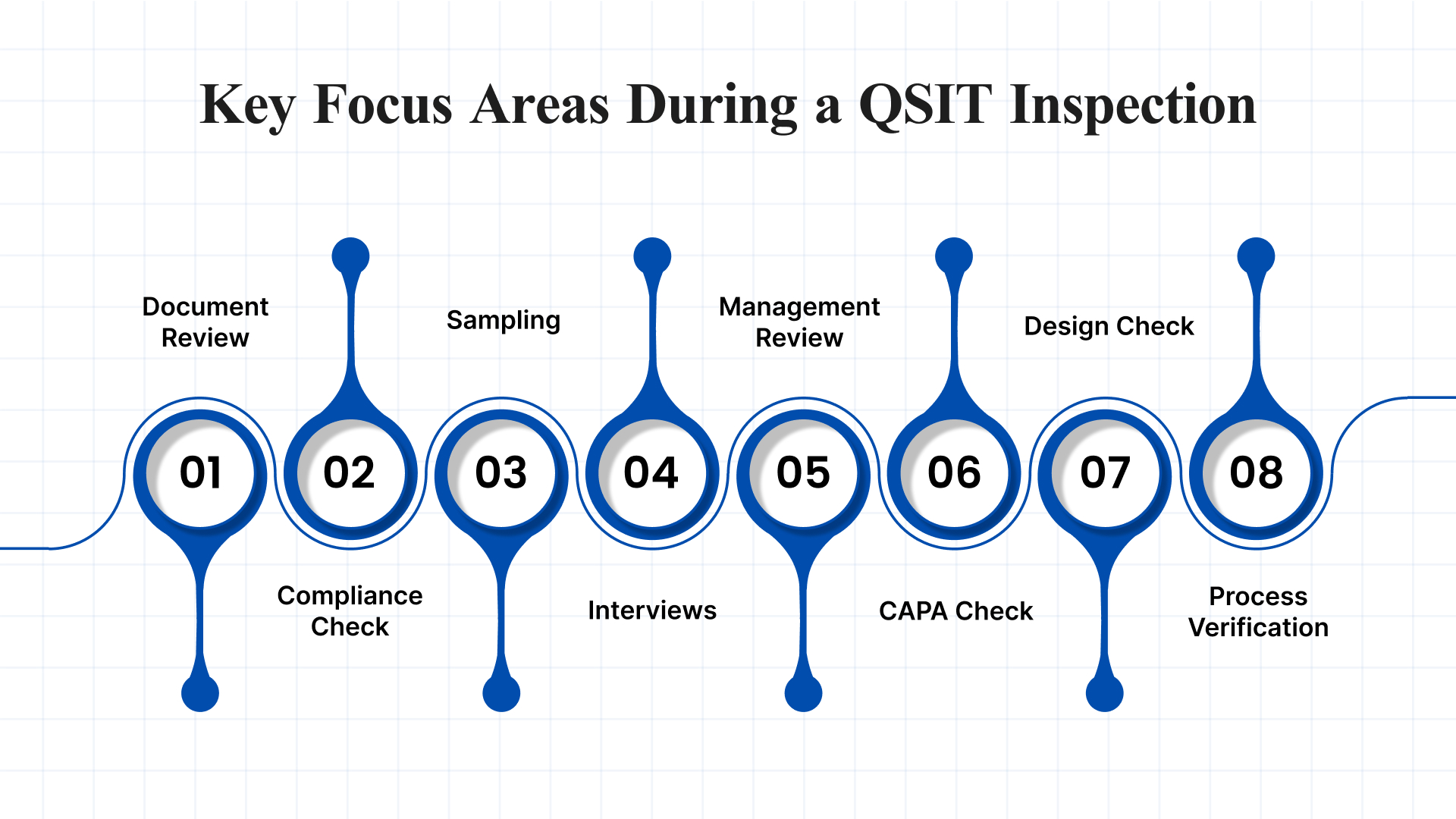

Key Focus Areas During a QSIT Inspection

The FDA’s QSIT inspection follows a structured approach, focusing on critical components of your quality system. Inspectors assess whether your documentation, implementation, and processes align with regulatory requirements and demonstrate a culture of compliance. Below are the core areas they will examine.

1. Document and Procedure Review First

One of the first steps in an FDA QSIT inspection is a thorough review of your documentation. Inspectors will evaluate everything from SOPs to quality manuals to verify that your systems are clearly defined and compliant. These documents must be up-to-date, accessible, and fully aligned with FDA regulations.

- Inspectors review Standard Operating Procedures (SOPs), quality manuals, and record-keeping systems.

- Documentation must reflect actual practices and regulatory expectations.

- Gaps, outdated documents, or inconsistencies can raise red flags.

2. Evaluation of Implementation and Compliance

Once documentation is reviewed, inspectors assess whether procedures are being followed in practice. This phase reveals if your team is truly executing what’s outlined in your policies and if your systems are delivering consistent compliance outcomes.

- Inspectors observe how procedures are implemented on the floor.

- Internal audit reports and training records are commonly reviewed.

- Evidence of real-time quality monitoring and issue resolution is key.

3. Sampling and Record Analysis

FDA inspectors will often verify compliance by sampling product lots and analyzing related records. This ensures that your products meet safety and quality requirements and that your documentation supports each decision made during production.

- Inspectors sample product batches and related testing data.

- Batch records, test results, and deviations are thoroughly reviewed.

- Discrepancies between records and product quality can indicate systemic issues.

4. Interviews and Personnel Interaction

Interviews are a critical part of the QSIT process. Inspectors speak with staff to evaluate their understanding of processes, roles, and regulatory responsibilities. Your team must be knowledgeable and confident in representing your quality system.

- Key personnel will be asked to explain SOPs and responsibilities.

- Lack of awareness or inconsistency in answers can impact inspection outcomes.

- Training records are reviewed to confirm competency across roles.

5. Management Controls Scrutiny

Inspectors will assess how management oversees and supports the quality system. This includes verifying whether senior leaders are actively involved in quality oversight, resource allocation, and decision-making when deviations occur.

- Management’s role in supporting quality is closely reviewed.

- Inspectors look for corrective action tracking and resource planning.

- Regular management reviews and follow-ups on CAPAs are expected.

6. Deep Dive Into CAPA System

The CAPA (Corrective and Preventive Action) subsystem is one of the most scrutinized areas in a QSIT inspection. It reflects how your company identifies, resolves, and prevents recurring quality issues, ensuring long-term compliance and safety.

- Inspectors check for timely identification of nonconformances.

- CAPA records must show root cause analysis and documented follow-up.

- Preventive actions should demonstrate systemic improvements.

7. Design Control Assessment (If Applicable)

If your company is involved in product design (such as devices or biologics), FDA inspectors will review how design inputs, outputs, validations, and changes are managed. This ensures the safety and effectiveness of the final product.

- Design plans, risk analysis, and validation protocols are inspected.

- Design reviews must be documented and traceable.

- Any design changes must follow documented change control procedures.

8. Production and Process Controls Verification

The inspection wraps up with a focus on production and process controls. Inspectors verify that equipment, facilities, and personnel are capable of producing consistent, compliant products under controlled conditions.

- Equipment maintenance, calibration, and environmental controls are assessed.

- Batch processing records are checked for compliance with SOPs.

- Any deviations in manufacturing must be investigated and documented.

Conclusion

FDA QSIT inspections are a critical part of ensuring your company remains compliant with regulatory standards. By focusing on the key areas outlined above, you can better prepare for an inspection and reduce the likelihood of noncompliance. Tools like Atlas Compliance provide a comprehensive solution for maintaining FDA inspection readiness, tracking inspections, updating regulatory changes, and preparing for audits, all from one place. Stay audit-ready and avoid surprises by utilizing AI-powered analytics and predictive compliance tools.

Need help staying prepared for your next FDA inspection? Book a demo with Atlas Compliance todayand see how our platform can help streamline your compliance efforts.

FAQs

1. What is an FDA QSIT inspection?

A QSIT inspection assesses the effectiveness of a company’s quality system based on FDA regulations. The inspector reviews your documentation, procedures, and implementation practices to ensure compliance with regulatory standards.

2. How can I prepare for a QSIT inspection?

To prepare, focus on ensuring your quality system subsystems are strong, that you maintain up-to-date documentation, and that your management team is well-trained and knowledgeable about FDA regulations.

3. How does Atlas Compliance help with FDA inspections?

Atlas Compliance helps you stay inspection-ready by offering access to comprehensive FDA inspection reports, predictive compliance analytics, AI-powered document search, and continuous regulatory surveillance. This helps you proactively manage compliance risks.

4. Why is a CAPA system important for FDA inspections?

A Corrective and Preventive Action (CAPA) system is critical because it shows the FDA that you can identify and address issues to prevent future problems. A well-documented and effective CAPA system can help mitigate inspection findings.